At Linp Chemical, we’ve worked closely with clients across the Middle East, Africa, and Southeast Asia for over two decades. We’ve seen many chemical buyers — especially those sourcing internationally for the first time — face similar challenges during this time.

Whether you’re sourcing water treatment, disinfection, or specialty applications, avoiding these common mistakes can help you save time, reduce risk, and get better results.

1) Focusing Only on Price — Not on Purity or Active Content

“This supplier is cheaper!”

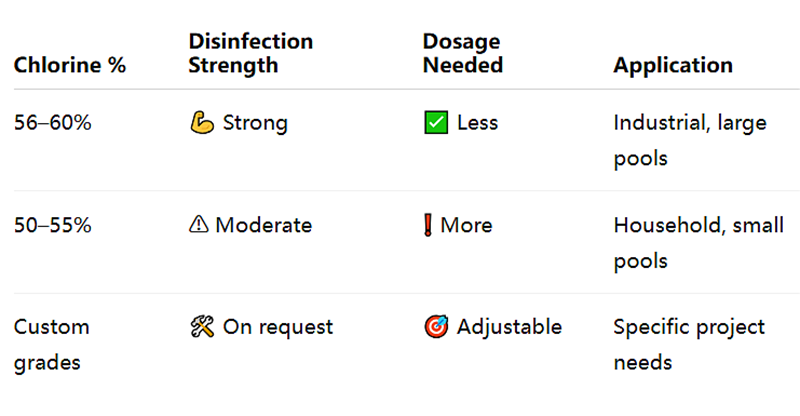

It’s tempting to choose the lowest quote, but that doesn’t always mean the best value. One key detail buyers often overlook is the concentration of active ingredients.

✅ Always compare technical specifications and test reports, not just the cost per ton. Focus on the cost per effective unit — this gives a more accurate picture of product performance and value.

(This is the application comparison of our SDIC with different chlorine contents.)

2) Overlooking Packaging Details

Packaging isn’t just about convenience — it directly affects product safety, shelf life, and compliance with local regulations.

Standard packaging might not withstand long-distance shipping or meet your country’s import standards.

✅ A reliable supplier should offer customized packaging solutions, such as:

Moisture-proof drums

UN-certified containers

Double-layered bags

Custom labeling based on your local requirements

(This is the detailed label of our TCCA outer packaging, which is fully customizable.)

3) Relying Only on Internal Quality Certificates

Some suppliers provide only in-house COAs (Certificates of Analysis), which may not be recognized by import authorities.

✅ Ask if the supplier can offer:

Third-party lab reports (e.g., SGS, Intertek)

MSDS and GHS-compliant labels

Country-specific compliance documentation

These documents are crucial for customs clearance, safety, and end-user confidence.

4) Assuming All Suppliers Have Stable Production & Lead Times

Not all suppliers are equal when it comes to production reliability.

Some offer fast quotes but delay deliveries or run into supply shortages.

✅ Work with manufacturers who have:

Real production capacity

Buffer stock for urgent needs

Transparent and consistent delivery timelines

This is especially important for projects with tight schedules or recurring orders.

5) Thinking Only About This One-Time Order

A “one and done” approach can create problems down the line — like inconsistent quality or lack of technical support.

✅ Instead, partner with a supplier who offers:

Ongoing support and communication

Scalable supply options

Flexible response to new requirements or changes in demand

A long-term relationship helps both sides work smarter and grow together.

What Makes a Reliable Chemical Supplier?

Here’s what our global clients say they value most:

✔️ Export experience & regulatory knowledge

✔️ Support for packaging, labeling & compliance documents

✔️ Product recommendations tailored to real applications

✔️ Stable factory capacity & long-term cooperation mindset

Linp Chemical – Your Trusted Partner Since 2004

From wastewater treatment chemicals to powerful disinfectants, we have helped customers across three continents solve supply chain challenges and improve procurement efficiency.

We understand the pain points — and more importantly, how to avoid them.

If you’re looking for a chemical supplier who prioritizes your needs, let’s talk.

Contact Us

Want to learn more or discuss your specific challenges?

Reach out today — we’re happy to help.